silicon

carbide

from nature

Hard Blue Si-Carbons represent the first single-solution that can transform agricultural residues into Silicon carbide abrasives and high-tech semiconductors. And, unlike Silicon carbide imported from China, our US- produced Silicon carbide is not subject to the 15% import tax.

Three in one

One man's garbage

While very much interested in biomass to fuels and energy, we observed that some agricultural residues contain a high Silicon dioxide content.

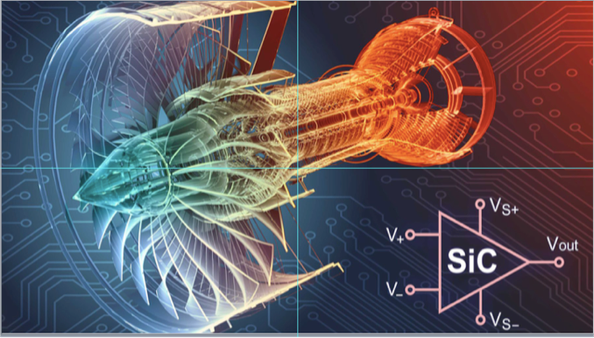

In researching applications for Silicon dioxide, we came across Silicon Carbide, which is widely used in industrial products, and which is the result of a chemical fusion of the Silicon dioxide (SiO2) and Carbon (C).

Traditionally, Silicon carbide is synthesized in ‘an Acheson furnace’ through the reaction between pure quartz sand (Silicon-dioxide) and petroleum coke (Carbon), an oil refining by-product.

Considerable energy and costs are involved in mining and transporting pure sand to a Silicon carbide production facility. Certain agricultural residues on the other hand contain both substances, and as such, these costs and energy usage can be eliminated. Furthermore, the organic residues have enough biomass to supply the energy needed to produce the silicon carbide.

Is another man's gold

We no longer simply landfill or incinerate residues from crop harvests, or milling. We analyze them and where possible transform them into high dollar renewable materials. So biomass can become feedstock for Silicon carbide, which in turn is used as abrasives or wafers for high-tech semiconductors.

Conversion of the ‘zero value’ residues into Silicon carbide abrasives and semiconductors is a sustainable and value-added solution. Hard Blue is building a Silicon Carbide production plant that will transform some 440,000 metric tons of organic residues per year into merchantable grades of Silicon carbide.